SpaceX CEO Elon Musk delivered an update about Starship, the company’s nest generation spacecraft, which is being designed for full, “rapid reusability.” Musk discussed the technology behind the design of Starship, which has evolved somewhat through testing and development after its original introduction in 2017.

Among the updates detailed, Musk articulated how Starship will be used to make humans interplanetary, including its use of in-space refilling of propellant, by docking with tanker Starships already in orbit to transfer fuel. This is necessary for the spacecraft to get enough propellant on board post-launch to make the trip to the Moon or Mars from Earth – especially since it’ll be carrying as much as 100 tons of cargo on board to deliver to these other space-based bodies.

These will include supplies for building bases on planetary surfaces, as well as up to 100 passengers on long-haul planet-to-planet flights.

Those are still very long-term goals, however, and Musk also went into detail about development of the current generation of Starship prototypes, as well as the planned future Starships that will go to orbit, and carry their first passengers.

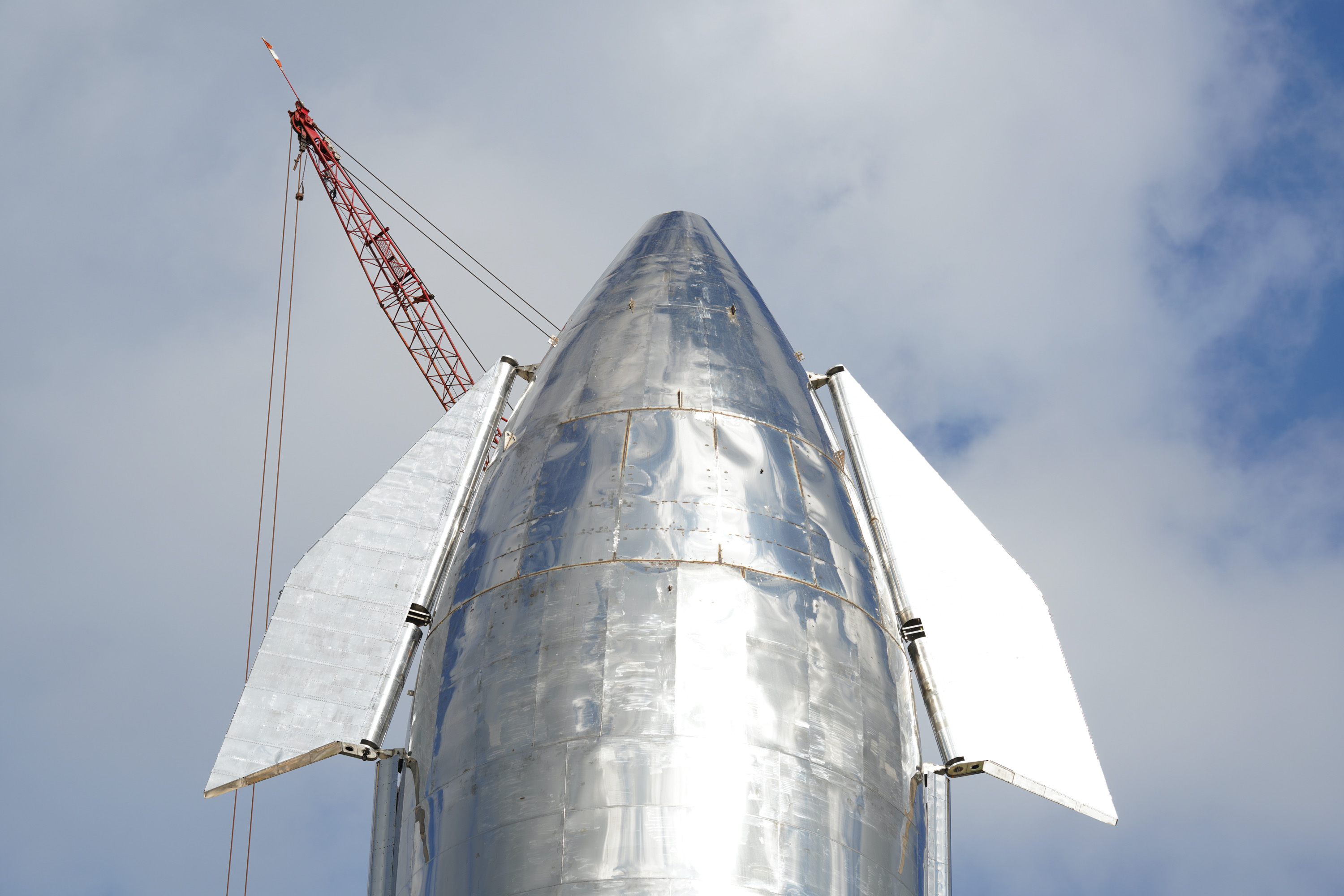

The Starship Mk1, Mk2 and the forthcoming Mk3 and Mk4 orbital testers will all feature a fin design that will orient the vehicles so they can re-enter Earth’s atmosphere flat on their ‘bellies,’ coming in horizontal to increase drag and reduce velocity before performing a sort of flip maneuver to swing past vertical and then pendulum back to vertical for touch-down. In simulation, as shown at the event, it looks like it’ll be incredible to watch, since it looks more unwieldy than the current landing process for Falcon boosters, even if it’s still just as controlled.

The front fins on the Starship prototype will help orient it for re-entry, a key component of reuse.

Musk also shared a look at the design planned for Super Heavy, the booster that will be used to propel Starship to orbit. This liquid-oxygen powered rocket, which is about 1.5 times the height of the Starship itself, will have 37 Raptor engines on board (the Starship will have only six) and will also feature six landing legs and deployable grid fins for its own return trip back to Earth.

In terms of testing and development timelines, Musk said that the Starship Mk1 he presented the plan in front of at Boca Chica should have its first test flight in just one to two months. That will be a flight to a sub-orbital altitude of just under 70,000 feet. The prototype spacecraft is already equipped with the three Raptor engines it will use for that flight.

Next, Starship Mk2, which is currently being built in Cape Canaveral, Florida, at another SpaceX facility, will attempt a similar high altitude test. Musk explained that both these families will continue to compete with each other internally and build Starship prototypes and rockets simultaneously. Mk3 will begin construction at Boca Chica beginning next month, and Mk4 will follow in Florida soon after. Musk said that the next Starship test flight after the sub-orbital trip for Mk1 might be an orbital launch with the full Super Heavy booster and Mk3.

Musk said that SpaceX will be “building both ships and boosters here [at Boca Chica] and a the Cape as fast as we can,” and that they’ve already been improving both the design and the manufacture of the sections for the spacecraft “exponentially” as a result of the competition.

The Mk1 features welded panels to make up the rings you can see in the detail photograph of the prototype below, for instance, but Mk3 and Mk4 will use full sheets of stainless steel that cover the whole diameter of the spacecraft, welded with a single weld. There was one such ring on site at the event, which indicates SpaceX is already well on its way to making this work.

This rapid prototyping will enable SpaceX to build and fly Mk2 in two months, Mk3 in three months, Mk4 in four months and so on. Musk added that either Mk3 or Mk5 will be that orbital test, and that they want to be able to get that done in less than six months. He added that eventually, crewed missions aboard Starship will take place from both Boca Chica and the Cape, and that the facilities will be focused only on producing Starships until Mk4 is complete, at which point they’ll begin developing the Super Heavy booster.

In total, Musk said that SpaceX will need 100 of its Raptor rocket engines between now and its first orbital flight. At its current pace, he said, SpaceX is producing one every eight days – but they should increase that output to one every two days within a few months, and are targeting production of one per day for early in Q1 2019.

Because of their aggressive construction and testing cycle, and because, Musk said, the intent is to achieve rapid reusability to the point where you could “fly the booster 20 times a day” and “fly the [starship] three or four times a day,” the company should theoretically be able to prove viability very quickly. Musk said he’s optimistic that they could be flying people on test flights of Starship as early as next year as a result.

Part of its rapid reusability comes from the heat shield design that SpaceX has devised for Starship, which includes a stainless steel finish on one half of the spacecraft, with ceramic tiles used on the bottom where the heat is most intense during re-entry. Musk said that both of these are highly resistant to the stresses of reentry and conducive to frequent reuse, without incurring tremendous cost – unlike their initial concept, which used carbon fibre in place of stainless steel.

Musk is known for suggesting timelines that don’t quite match up with reality, but Starship’s early tests haven’t been so far behind his predictions thus far.